Integrated Building Technology (IBT) is a series of architecture courses that inform students on different building materials, environmental factors of design, and exposure to new program and rendering skills.

Intro to IBT (Fall 20222)

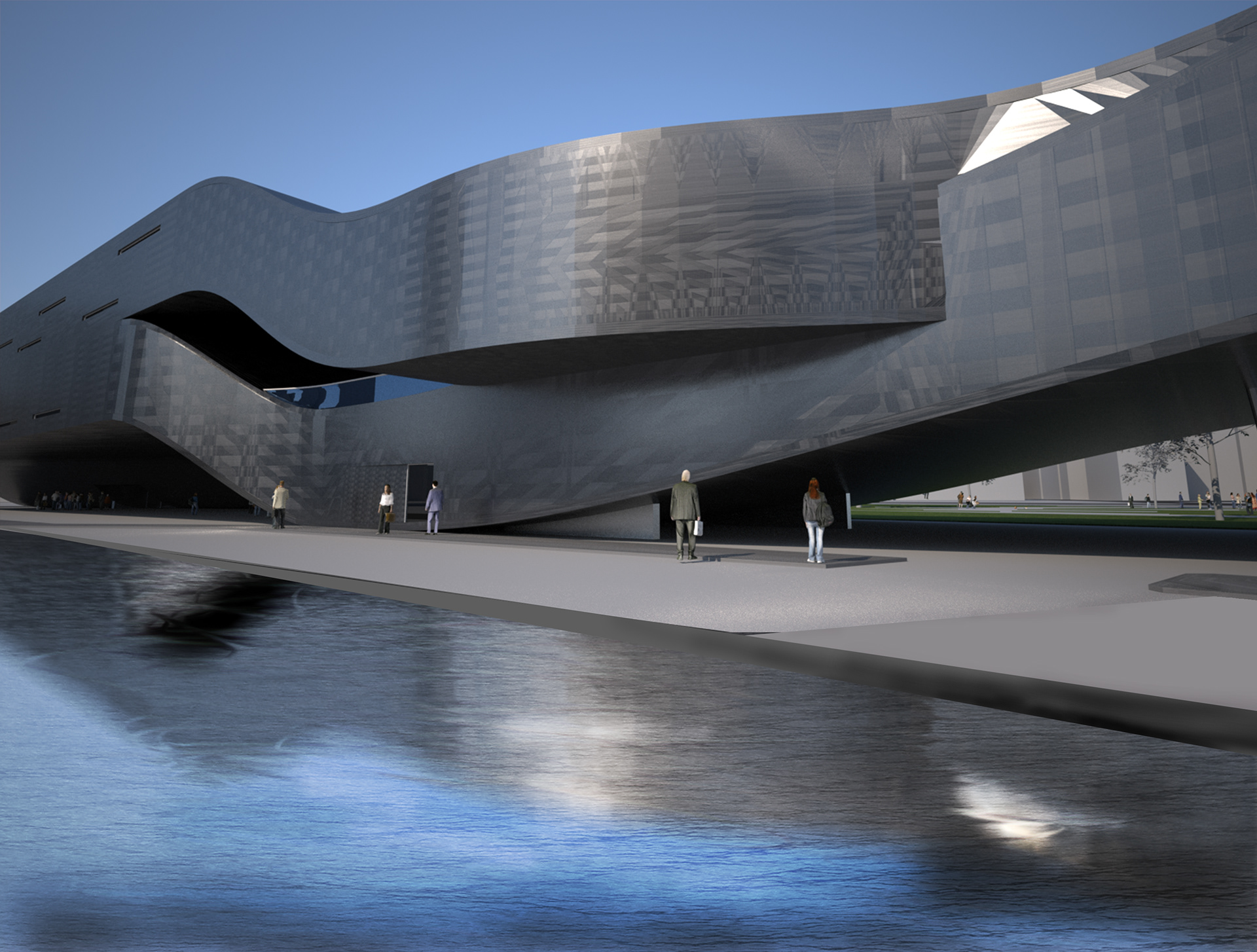

This course served as an introductory class on how students can use Photoshop to better visualize their design projects and ideas through diagrams and material renderings.

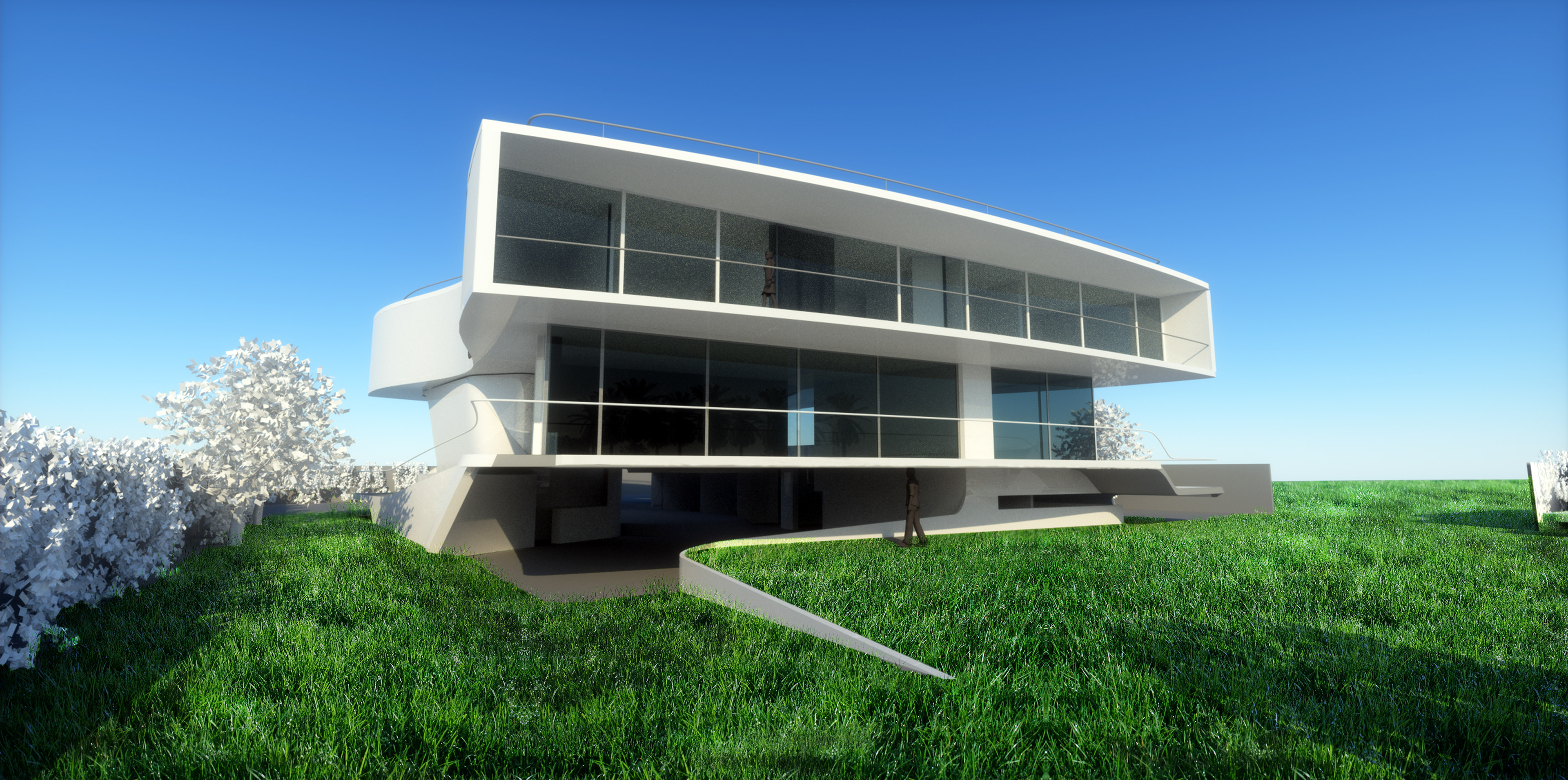

Shading systems exercise done in Photoshop on a Rhino model file.

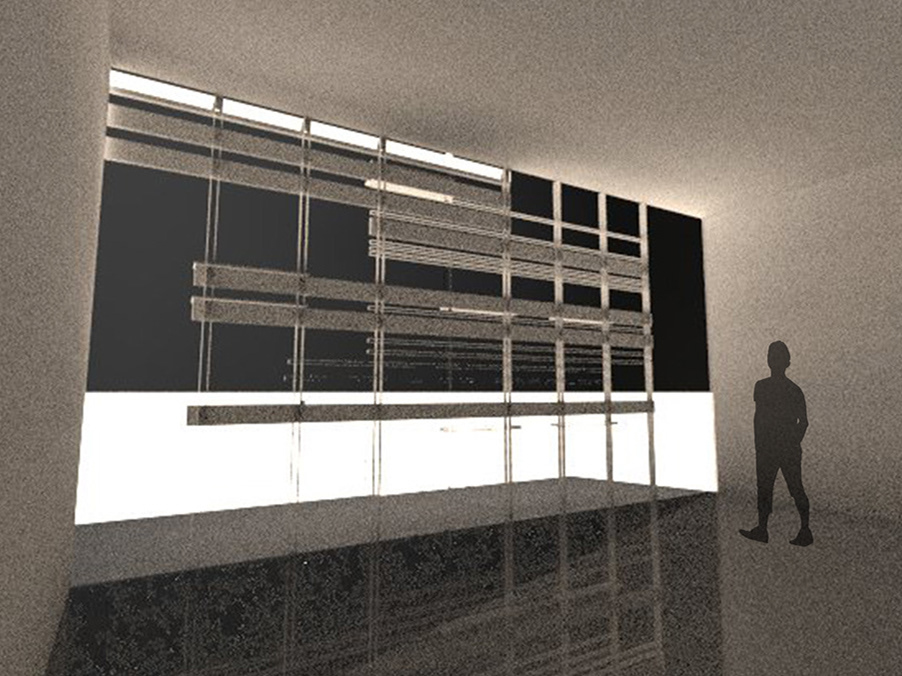

Water mirror and blurring effect done in Photoshop